WeldWrap® HD

Heavy Duty Hook & Loop Closure

Techflex®'s NEW & Improved WeldWrap® HD construction is braided from silica yarns rather than Fiberglass. The heavy duty hook and loop closure ensures a tight seal, and allows WeldWrap® HD to be installed easily over existing assemblies. WeldWrap® HD also provides a high level of abrasion and penetration protection to increase the useful life of any hoses exposed to rough or abrasive surfaces.

- Acrylic Coated Fiberglass

- Extremely Abrasion and Cut Resistant

- Will Not Burn or Support Combustion

- Resists Common Chemicals & Solvents

- Easy to Install

- Easy Hook and Loop Wraparound Installation

- Temperature Range: –62.5°F to 500°F (-54°C to 260°C)

- Intermitten Exposure: Up To 2,000°F

Why Providing Extra Protection to Welding Hoses Is Important

Safety: Welding hoses carry gases that are used in the welding process, such as oxygen and acetylene. These gases are highly flammable and can pose a significant safety risk if they come into contact with sparks, flames, or other sources of heat. Protecting your welding hoses with additional layer of protective material helps to reduce the risk of fire and explosion if your hoses become compromised.

Durability: Welding hoses are typically made from materials that are resistant to heat and flames, but they can still be damaged by prolonged exposure to high temperatures, sparks, and other hazards. By covering your hoses with high temperature sleeving, you can help to extend their lifespan and ensure they remain in good condition longer.

Job Efficiency: Damaged welding hoses can leak gases or reduce the flow of gas to the welding torch, which can negatively impact the quality and efficiency of the welding process. By protecting your hoses, you can help to maintain a consistent flow of gas and ensure that your welding equipment is functioning properly and safely.

Tips for Installing & Terminating Braided Sleeving

How To Determine What Diameter Sleeving You Need

Bundle the cords that you’ll be covering and measure the diameter of the bundle. If you want a snug fit, choose a braided sleeving option with a slightly smaller diameter than that of your cables. If you want a loose and flexible fit, choose a braided sleeving option with a diameter that is equal to or slightly larger than that of your cables. Keep in mind that braided sleeving loses 2% to 3% of its length when it expands. Be sure to plan accordingly!

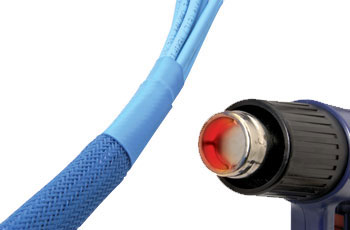

How To Terminate Sleeving with Heatshrink Tubing

Heatshrink Tubing is the ideal way to create a tight, professional finish on any wire, hose or cable management project. Once shrunk, the tubing will hold its reduced state, even at elevated temperatures. This application can be used to protect, color code, brand, or secure ends or sections of braided sleeving. A Heat Gun is required to properly apply heatshrink tubing. You can find a guide to the proper technique for working with heatshrink tubing Here.