Aviation Wire Harness Sleeving Kits

Wire Protection For Your Aircraft

With Techflex's Aviation Kits you have the perfect choice for minimizing flame spread when it is of the utmost importance. Organic flame inhibitors ensure the material does not support combustion and meets aviation industry standards.Quick and easy installation with Flexo FR, a widley used material in the aerospace industry. Easy to use even over long wire runs.

- 20 ft - 1/4" Black w/ White Tracer Flexo® FR

- 20 ft - 3/8" Black w/ White Tracer Flexo® FR

- 20 ft - 1/2" Black w/ White Tracer Flexo® FR

- 20 ft - 3/4" Black w/ White Tracer Flexo® FR

- 20 ft - 1/4" White w/ Black Tracer Flexo® FR

- 20 ft - 3/8" White w/ Black Tracer Flexo® FR

- 20 ft - 1/2" White w/ Black Tracer Flexo® FR

- 20 ft - 3/4" White w/ Black Tracer Flexo® FR

What Does ‘Flame Retardant’ Mean?

Flame retardant refers to a substance or material that is designed to resist or delay the ignition and spread of flames. Flame retardants work by interrupting the chemical reactions that occur when a material is exposed to heat or flames. They can prevent or slow down the release of flammable gases, reduce the amount of oxygen available for combustion, or create a protective layer that shields the material from the fire.

Why Is Flame Retardant Wire Protection Important for Aviation?

Using flame retardant sleeving can help prevent or delay the spread of fires in aircraft. In the event of a fire, the flame retardant materials used in wire protection can slow down the rate at which the fire spreads, giving passengers and crew members more time to evacuate the aircraft.

Tips for Installing & Terminating Braided Sleeving

How To Determine What Diameter Sleeving You Need

Bundle the cords that you’ll be covering and measure the diameter of the bundle. If you want a snug fit, choose a braided sleeving option with a slightly smaller diameter than that of your cables. If you want a loose and flexible fit, choose a braided sleeving option with a diameter that is equal to or slightly larger than that of your cables. Keep in mind that braided sleeving loses 2% to 3% of its length when it expands. Be sure to plan accordingly!

How To Cut Sleeving with a Hot Knife

To ensure a frayless, professional end on any installation, it is recommended that expandable braided sleeving be cut with a hot knife, rope cutter, or similar tool. We offer a wide variety of Hot Knives for different applications, including handheld knives, table knives, and replacement blades. Watch our video on Using A Hot Knife To Cut Braided Expandable Sleeving.

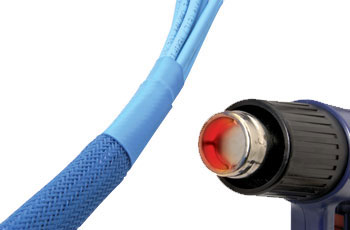

How To Terminate Sleeving with Heatshrink Tubing

Heatshrink Tubing is the ideal way to create a tight, professional finish on any wire, hose or cable management project. Once shrunk, the tubing will hold its reduced state, even at elevated temperatures. This application can be used to protect, color code, brand, or secure ends or sections of braided sleeving. A Heat Gun is required to properly apply heatshrink tubing. You can find a guide to the proper technique for working with heatshrink tubing Here.