Dura HVAC Wrap

Lightweight Wrap To Assist HVAC Installers

With the introduction of new building code regulations regarding protection of foam insulation on HVAC line sets, Techflex® has developed a new lightweight wrap to assist installers with code compliance. Our new Dura HVAC Wrap is constructed of a tightly woven breathable polyester shell that offers protection from wind, rain, mildew, UV Rays and abrasion. The extra wide hook and loop closure assists in covering multiple diameters quickly and easily for a tight fit.

Building Code Compliant: C 403.2.10.1 & R 403.4.1

- 600 Denier Polyester With Urethane Coating

- Water Repellent

- Mildew Resistant

- Building Code Compliant C 403.2.10.1 & R 403.4.1

- Meets California Building Energy Standards

- ASTM E96 Class III Vapor Retarder

Why Do I Need To Protect The Foam On My HVAC System?

Who doesn’t enjoy a nice sunny day. We love the sun. It’s great - except for those UV rays! Ultraviolet rays given off by the sun are a destructive force to be reckoned with. It’s menacing effects can be seen everywhere from roofs to roads - even the wrinkles of your grandparents were caused by UV.

These ultraviolet rays also tear pipe insulation to shreds making repeat service calls to your units a nagging reality. Cracked insulation means an AC unit that has to work harder to keep a building cool. A harder working unit means more energy being consumed. This has become so much of a problem, in fact, that California, Arizona, and Florida have made it mandatory to protect the foam by covering it with paint or by some other means.

Paint is also affected by UV, making it useful for about 2 years. Now, you have to drop what you’re doing, make a service call and repaint it. Techflex® has some solutions. Introducing F6® and Dura HVAC Wrap! Not only are these a faster way to protect your foam pipe insulation, you only have to do it once. They resist harmful UV, they’re abrasion resistant, and attractive to boot. Both will stand up to that bully in the sky and won’t wrinkle like grandpa’s mug, saving you from having to take time out of your important installs.

Tips for Installing & Terminating Braided Sleeving

How To Determine What Diameter Sleeving You Need

Bundle the cords that you’ll be covering and measure the diameter of the bundle. If you want a snug fit, choose a braided sleeving option with a slightly smaller diameter than that of your cables. If you want a loose and flexible fit, choose a braided sleeving option with a diameter that is equal to or slightly larger than that of your cables. Keep in mind that braided sleeving loses 2% to 3% of its length when it expands. Be sure to plan accordingly!

How To Cut Sleeving with a Hot Knife

To ensure a frayless, professional end on any installation, it is recommended that expandable braided sleeving be cut with a hot knife, rope cutter, or similar tool. We offer a wide variety of Hot Knives for different applications, including handheld knives, table knives, and replacement blades. Watch our video on Using A Hot Knife To Cut Braided Expandable Sleeving.

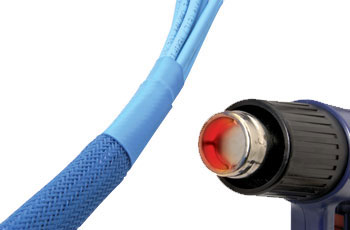

How To Terminate Sleeving with Heatshrink Tubing

Heatshrink Tubing is the ideal way to create a tight, professional finish on any wire, hose or cable management project. Once shrunk, the tubing will hold its reduced state, even at elevated temperatures. This application can be used to protect, color code, brand, or secure ends or sections of braided sleeving. A Heat Gun is required to properly apply heatshrink tubing. You can find a guide to the proper technique for working with heatshrink tubing Here.